Despite widespread clinical applications in drug delivery, biosensing, and tissue modulation—think pacemakers, glucose monitors, cochlear implants, electro-pharmaceutical therapies—bioelectronic devices tend to be rigid, power-inefficient, and mechanically and chemically invasive to living cells. Traditional materials like platinum, iridium oxide or titanium nitride tend to be bulky. Polymer-based materials can become electrochemically unstable on repeated use. While coating surfaces with carbon nanomaterials can reduce help, it can add to the bulkiness of devices, and also cause in vivo complications.

To surmount these shortcomings, researchers at the Tian Research Lab at the University of Chicago have been working on a carbon-based nanomaterial that is more biocompatible, electrically efficient, and non-toxic. A paper describing their work was published in 2020, and in August 2021, they took out a patent for the technology. Focusing on the need for greater flexibility and stability, the research team developed a new method for fabrication of carbon-based bioelectronic devices and interfaces.

"Our work deals mostly with synthesis of…a mesoporous carbon membrane," says Aleksander Prominski, a research student at the lab and co-author. Unlike earlier carbon-based bioelectronic devices that used polymers as a binding material, this one is monolithic, or binder-free. "If you look into other carbon-based materials that are either graphene-based or carbon nanotube-based, they always require some type of matrix or adhesive [holding the material] together," Prominski adds. "In our case…because we don't use any type of adhesives…it both improves the conductivity and stability of this material."

An essential characteristic of nanoscopic bioelectronic materials is their ability to self-assemble, which Prominski explains is to "form structures based on [their] chemical and physical properties [rather than] through the human interaction." For this, the researchers used micelles, an aggregation of charged atoms or molecules, dispersed in a liquid to form a colloidal suspension. "The micelles are like a separate face of surfactants…which then causes segregation of material parts during the self-assembly process."

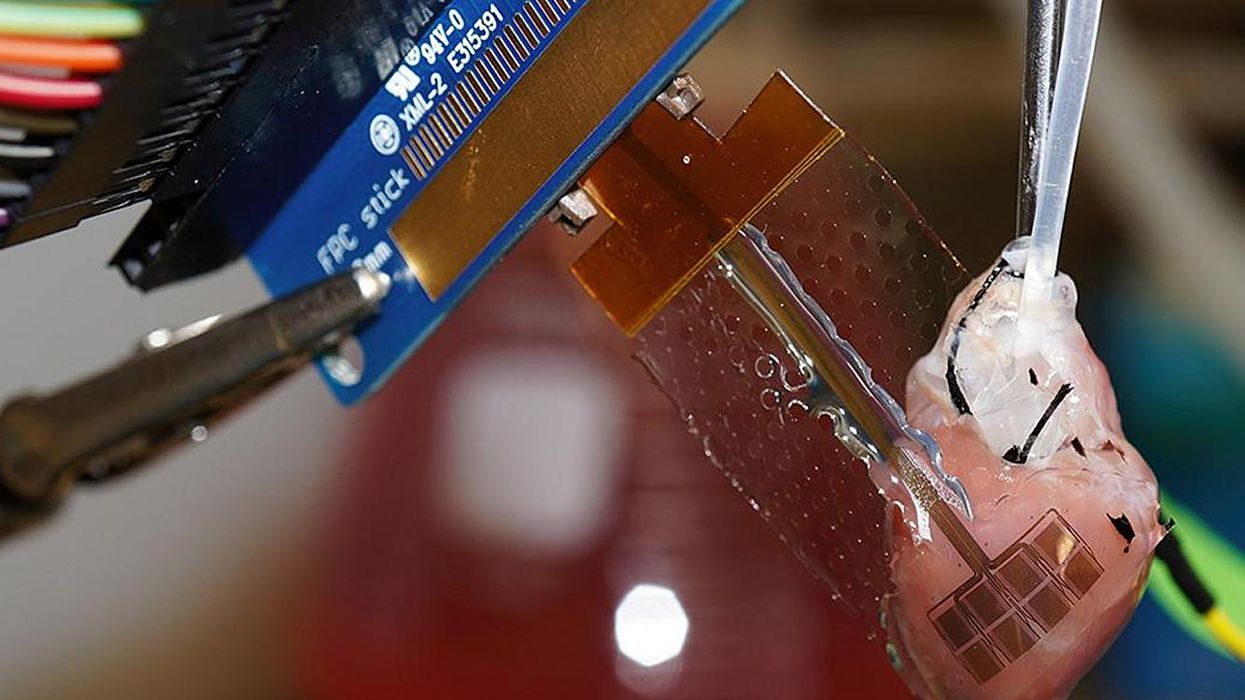

Another unique aspect of the study, says co-author Lingyuan Meng, is the use of interdigitating electrodes. This design shrinks the size of the electrode for subcellular interfaces. "Traditional electrodes will generate a lot of toxic side-products," she says, for example, Faradaic reactions, or charge-transfer reactions, at the surface of electrodes. These result in toxicity that can damage living cells. "So [with the new interface] you have a very healthy way to stimulate a cell." The scientists were able to demonstrate capacitive control of the electrophysiology of isolated hearts, retinal tissues and sciatic nerves of rats, as well as bioelectronic cardiac sensing.

Bioelectronics and electroceuticals are tipped to be be the next big wave of device therapeutics, and the global market is expected to reach over US $25 billion in 2021. However, there are still many obstacles to surmount, including understanding the biological principles behind cellular stimulation and response in much greater detail. "The big challenge is [to] really know what's exactly going on in the biological system," says Meng, as there are a lot of underlying mechanisms taking place at the subcellular level that are unknown: "We see a phenomenon, but we are not actually sure what's happening in the cells."

While this study gives insight into how cells interact with materials, and how more biocompatible materials with better electrochemical properties can be beneficial for eliciting responses, Prominski says that it is now time to dig a little bit deeper into the biophysics of the cells and issues. "And then the other challenge would definitely be translation of those materials into actual applications." These include flexible electrical biosensing and bioelectric therapeutics of the future.